Services

Our in-house services include:

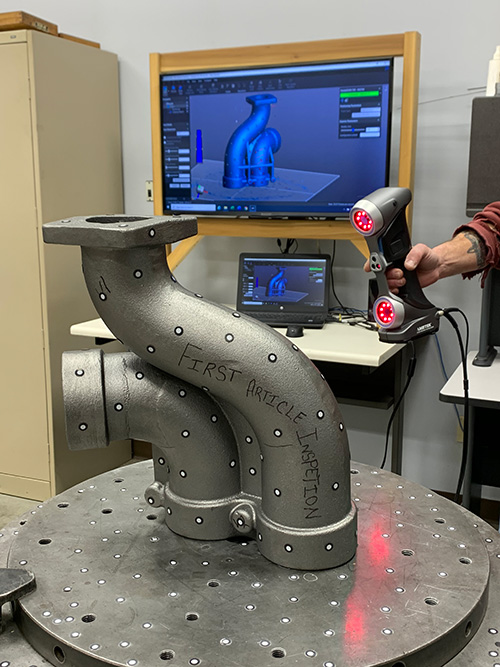

3D Scanning

Cunningham Precision Group provides 3D scanning services, bringing digital benefits to manufactured parts. Our 3D scanning process uses precision laser scanners to capture millions of data points for use in:

- Manufacturing

- Rapid Prototyping

- Reverse Engineering

- Documentation/CAD drawings

Pattern Shop

- Quick turn around on quotes

- Over 50 years in the industry

- Collaboration with customers on castability

- Creating fit / function models

- Gating designed using solidification software

- Full 3D Computer Aided Design of tooling

- Gating integrated into tooling

- Full CNC machined tooling including core boxes

- Tooling produced from a variety of materials

- 6 CNC Vertical Mills

- Rework existing outside tooling

Foundry

- No Bake / Airset molding

- Specializing in prototype casting

- Pre and post production volumes

- Aluminum casting up to 500 lbs

- Grey and Ductile iron casting up to 1500 lbs

- High Silicon Moly and Ni-Resist castings

- Spectrometer element analyses for all metals

- Full sand test lab

- In-House pattern storage

- Pour 3D printed sand cast molds

Machine Shop

- CNC 3D fixturing using tooling files

- Precision 3D Machining

- Horizontal, Vertical and Lathe CNCs

- Automated Coordinate Measuring Machine

- Pressurized and heated leak testing station

- Component assemble

- Warehousing of machined and un-machined parts

CONTACT US

Mailing: P.O.Box 854

Columbus, IN 47202

Shipping: 4399 North US Highway 31

Columbus, IN 47201

We are eager to partner with clients who have unique engineering, casting and machining needs.

Click the link below to complete our contact form and we will be in touch shortly.

Copyright © Cunningham Precision Group

( Formerly CE Systems and Cunningham Pattern & Engineering )

Web published by Marketing Options, LLC.