3D Scanning Improves Accuracy and Lowers Costs

Cost Savings

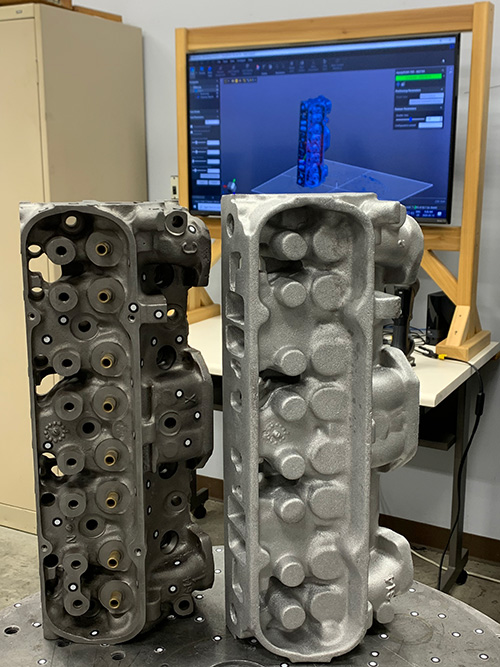

3D scanning brings digital benefits to manufactured parts. Once scanned, 3D models save up to 80% of costs over traditional routes to modify and recreate the parts. Additionally, scanning measures parts to the highest specifications and provides validation of the precision of the manufacturing.

Quality

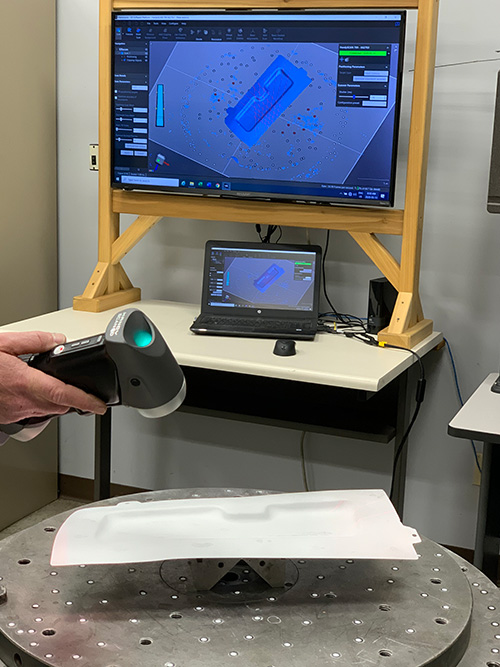

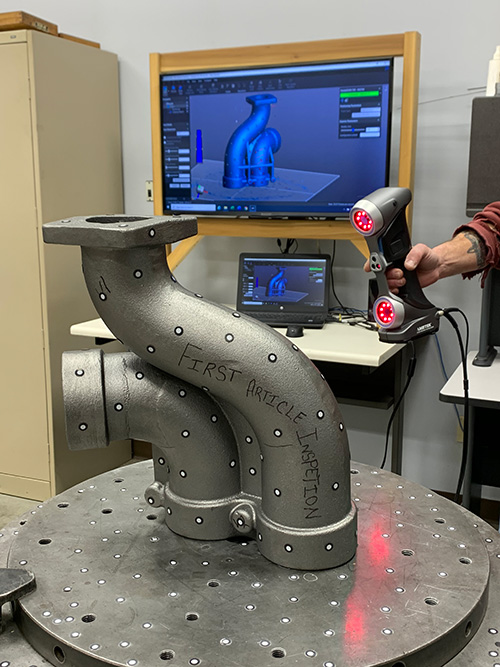

Using the 3D scanning process for dimensional layout, we compare the geometry of the part to the CAD model geometry provided by the customer. We do a best-fit scenario, utilize the tolerances allowed, and this information quickly shows any dimensional issues with the part. 3D scanning speeds up the layout process to allow you to complete all your quality work and get parts approved faster. This is why Cunningham Precision Group has added 3D scanning to its vast array of services.

Reverse Engineering

The 3D scanning process is also used to create a 3D CAD model for reverse engineering. If you have an old part and do not have any blueprints or CAD models, a 3D scan of the part will provide you with a 3D CAD model for any future manufacturing needs.

Improved Production

This technology is also great to monitor wear on stamping dies, injection molds, and foundry patterns. By scanning your tool you’ll be able to compare the tool to the original CAD model for that tool.

If you are required to maintain a consistent manufacturing process, or if you have a stringent customer — implementing this technology will give you the ability to stay on task and keep up production.

CONTACT US

Mailing: P.O.Box 854

Columbus, IN 47202

Shipping: 4399 North US Highway 31

Columbus, IN 47201

We are eager to partner with clients who have unique engineering, casting and machining needs.

Click the link below to complete our contact form and we will be in touch shortly.

Copyright © Cunningham Precision Group

( Formerly CE Systems and Cunningham Pattern & Engineering )

Web published by Marketing Options, LLC.